Scada Automation

SCADA Automation New Zealand

ACSE’s Supervisory Control and Data Acquisition (SCADA) automation provides information integration you can rely on. No matter which industry you work in, be it manufacturing, packaging, or energy, SCADA automation systems can dramatically improve your business performance.

SCADA Automation With ACSE

Our SCADA capabilities allow you to monitor and control your processes using high-quality data and software solutions. With real-time functionality, our SCADA automation software provides information on your plant’s overall performance.

ACSE works with the latest version of Azure human-machine interface (HMI) software, Wonderware InTouch software, Citect SCADA software and Ignition SCADA software to give you the best-in-class automation solutions. Our systems are easy to install, highly efficient, and firmly integrated with your control and IT processes.

The Benefits Of Software Automation

SCADA software allows operators to interact with machines and equipment. This permits significantly more data for your business to work with, resulting in faster decision-making and faster resolution when problems arise.

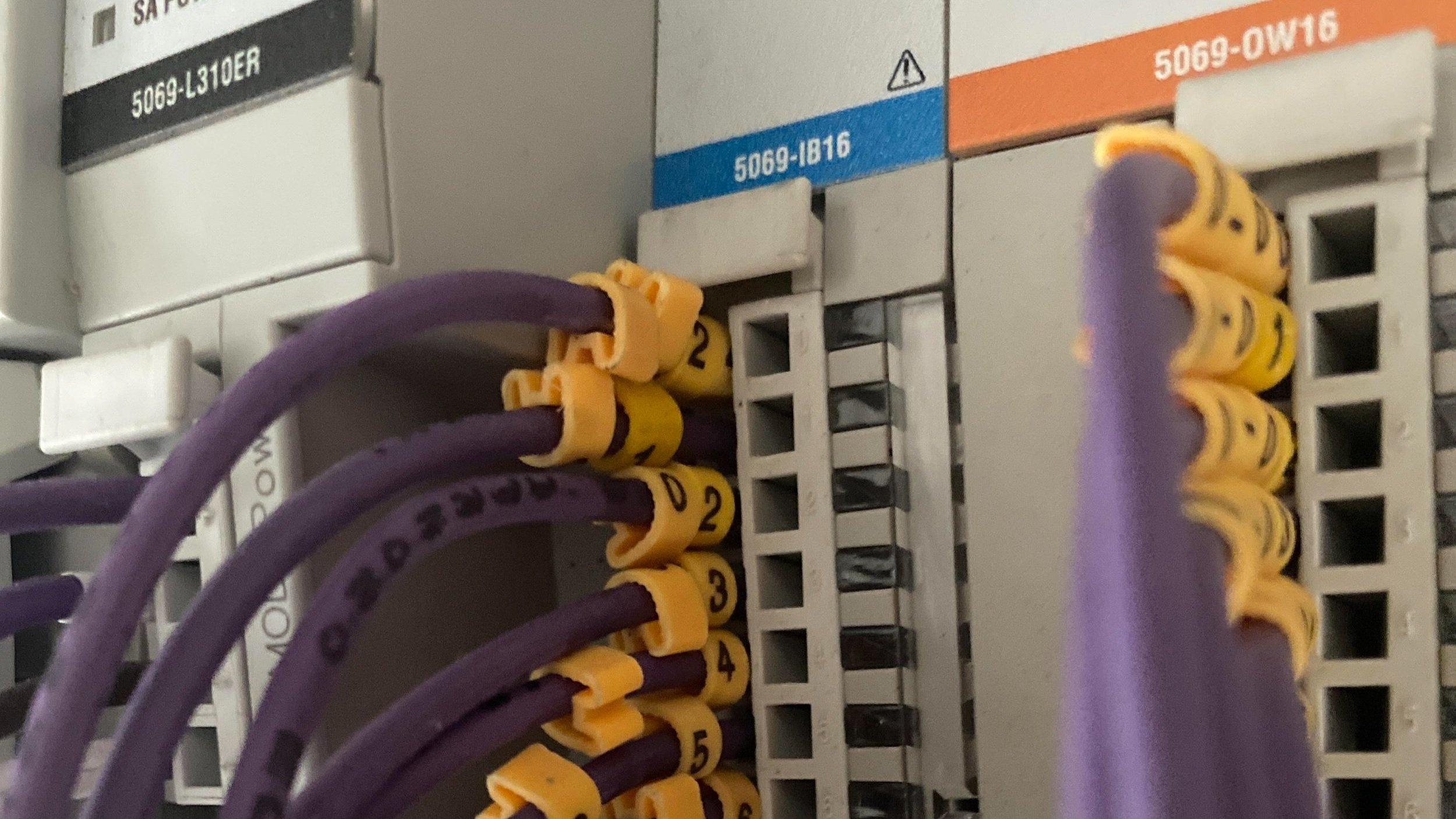

By using refined remote terminal units (RTUs) and programmable logic controllers (PLC), machine sensors can pick up on the slightest changes in your production line.

You can zoom in on specific pieces of equipment and parts of that equipment or zoom out for a broader overview. This allows for the ability to identify and resolve issues as they take place, leading to far lower costs and far greater consistency in your workflows.

The Benefits Of SCADA

SCADA software allows operators to interact with machines and equipment. This permits significantly more data for your business to work with, resulting in faster decision-making and faster resolution when problems arise.

By using refined remote terminal units (RTUs) and programmable logic controllers (PLC), machine sensors can pick up on the slightest changes in your production line.

You can zoom in on specific pieces of equipment and parts of that equipment or zoom out for a broader overview. This allows for the ability to identify and resolve issues as they take place, leading to far lower costs and far greater consistency in your workflows.