Food Industry

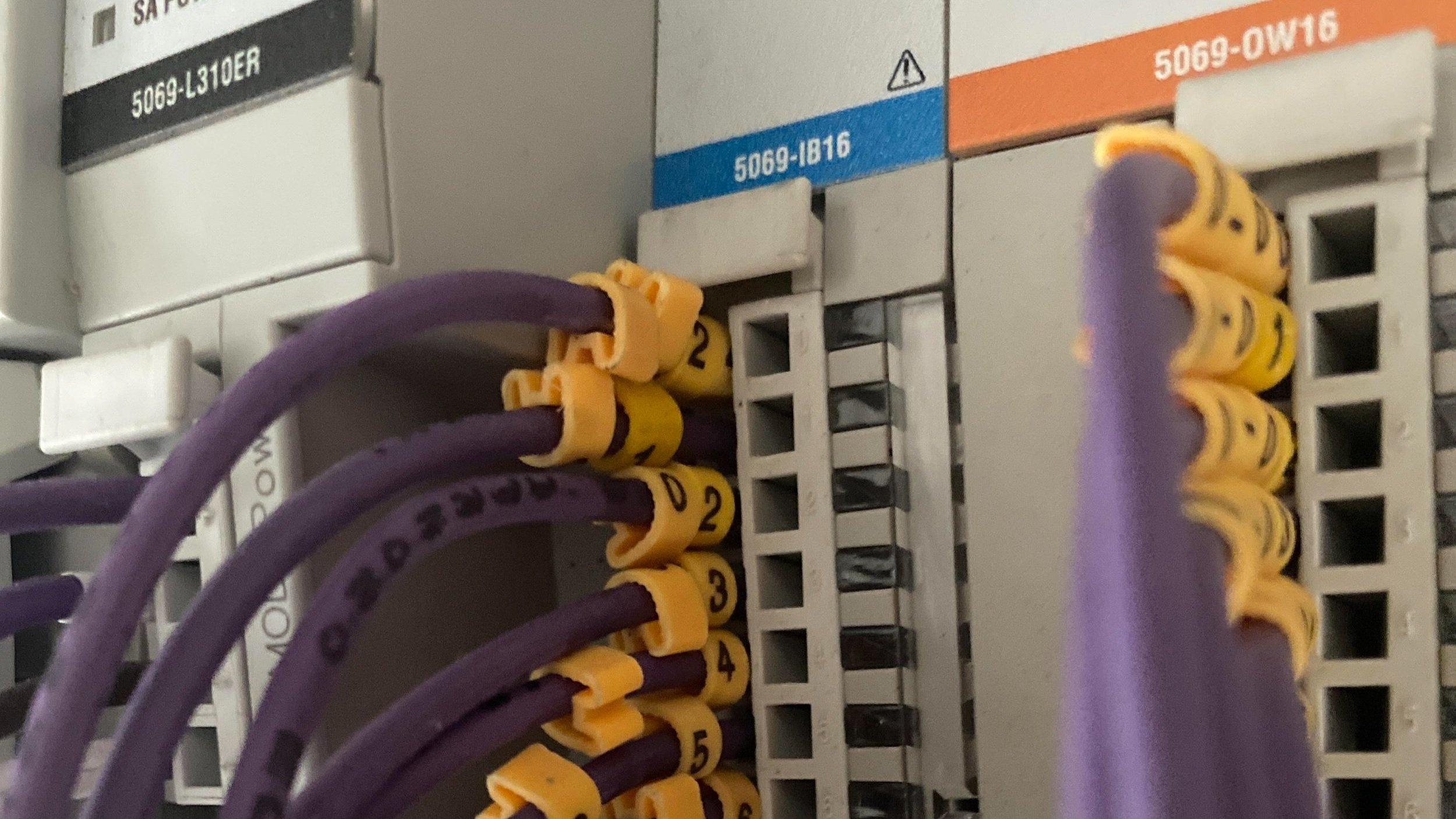

ACSE Limited has designed the Electrical and Automation Systems for a bulk material handling and recipe batching plant from P&ID (piping and instrumentation diagrams) schematics.

Flour, sugar and by products was discharged from bulk bag off loaders and transferred to a blender. Recipes was selected from a touch screen and each product was weight and batched accordingly.

The mixed products were transferred to a packing line where the ingredients were packed for retail.

ACSE Limited has designed the electrical installation, the main MCC with PLC controllers and the operator stations with touch screen panels where the operators selected the required recipes.

The touch screens were also used for CIP (clean in place) and general plant control.

AB Foods - New Zealand

Sugar – Bulk material handling

ACSE limited designed the Electrical and Automation Systems for a bulk sugar handling system. The PLC controller program, conveyed sugar from a bulk storage tank to small holding hoppers. The sugar is transferred from the holding hoppers to a bag filler.

The operator use the SCADA control system on the touch screen to stop and start the process and monitor any alarms. The touch screen was also used for CIP (clean in place)

Sara Lee - Australia

Crumb handling plant

ACSE limited has designed an Electrical and Automation Systems to unload crumbs from a bulk bag off loader and convey the product to a hopper. The crumbs were then transferred from the hopper to the process line where the crumb base was formed for the cakes.

For automation engineering NZ-wide, get in touch with ACSE today.