Machine Breakdowns

Are machine breakdowns interfering with your productivity?

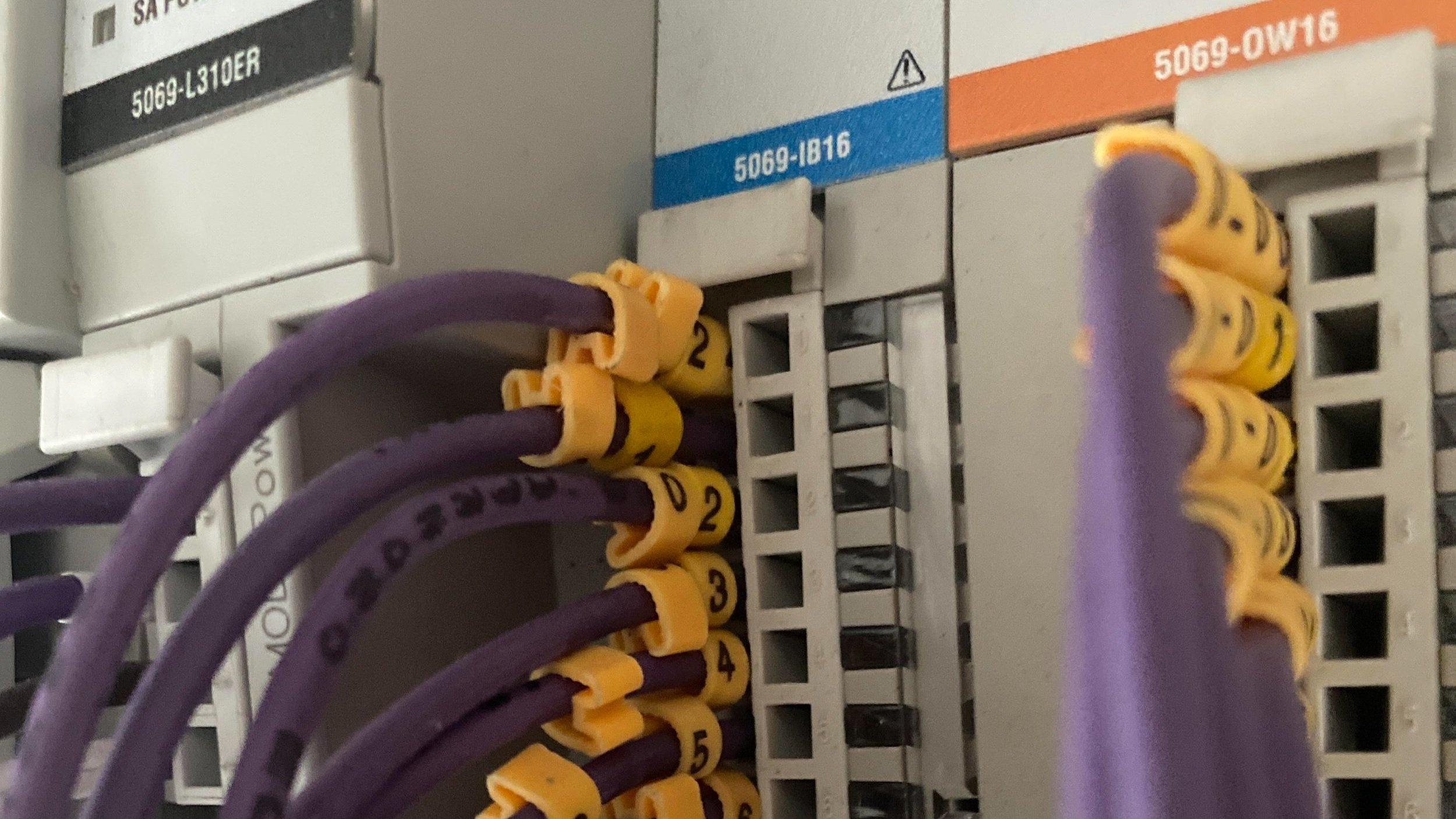

ACSE Limited specialises in machine repairs and upgrades. We repair faulty control gear on old and new machines. We also replace old equipment with the latest hardware and technology along with programs that improve machine performance. This avoids those constant breakdowns that impact your productivity.

We do fault-finding on all PLC brands, across many different industries, with in-depth experience across the food industry, packaging industry, plastic industry, textile industry, and all types of processing plants and delivery systems.

We offer a full upgrade on old machine control systems, instrumentation- sensors and touch screens. We transfer the existing control software into new, up to date controllers, we also upgrade existing touch screens to new, larger format touch screens with the latest easy-to-read technology.

The consequences of machine breakdowns

Machine breakdowns stop production, no production means no income. This is a situation that no product manufacturer wants to be caught in. Machine breakdowns lead to lost production time, missed delivery deadlines, reduced quality of products, more rework and more scrap, as well as increased operating costs – all of that eats into your profit. If your machines are not performing reliably, it will impact your reputation with your customers, and frustrate the down-stream supply chain. Do not take that risk.

Our team of Engineers can get you up and running fast. For information about how we can assist with machine breakdowns and reduce downtime for your business, simply get in touch with ACSE today. Talk to us about the challenges you are facing – we will help.