Safety PLC’s

Programmable Safety Controller

Safety First: Why Programmable Safety Controllers Matter in NZ Industries

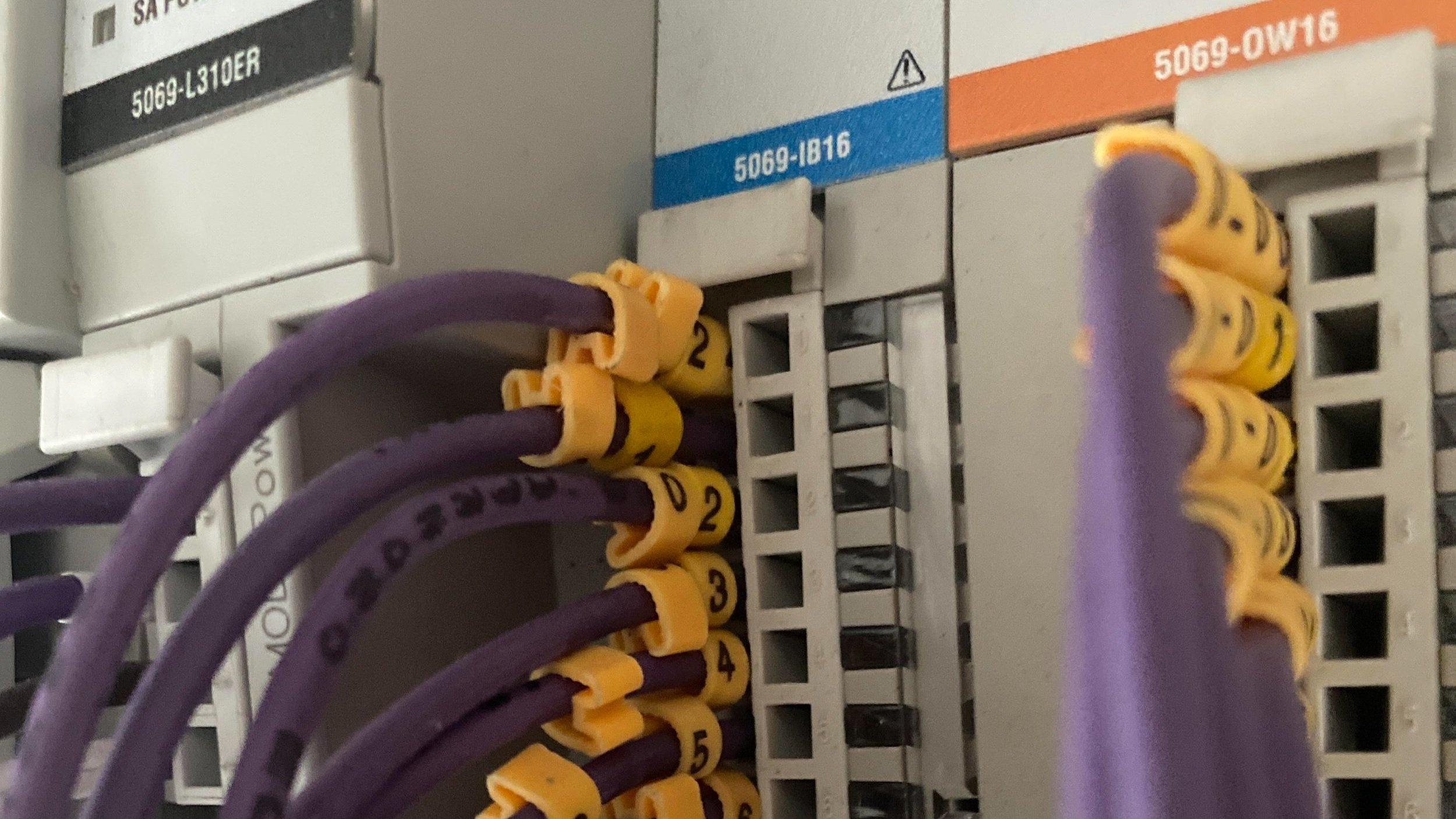

In today's fast-paced and automated industrial environments, safety is not just a priority—it’s a responsibility. Whether you're operating in manufacturing, food processing, packaging, or chemical industries, ensuring worker and machine safety while maintaining productivity is critical. That’s where the Programmable Safety Controller (PSC) comes in.

A Programmable Safety Controller NZ businesses can rely on is a specialised type of PLC (Programmable Logic Controller) that manages safety-critical functions. Unlike standard PLCs, Safety PLCs or PSCs are built with fault detection, system redundancy, and compliance with international safety standards like IEC 61508 and ISO 13849. These features ensure that critical safety devices such as emergency stop buttons, safety light curtains, interlocks, and pressure-sensitive mats operate with maximum reliability and minimal risk.

Why Choose a Programmable Safety Controller?

There are several benefits to integrating a Programmable Safety Controller NZ facilities can adopt:

Reduces Downtime: By quickly detecting and isolating faults, safety controllers can help prevent unplanned shutdowns and system-wide failures.

Ensures Operator Safety: PSCs are designed to react immediately to hazards, helping protect workers from injury.

Streamlines Compliance: With built-in safety logic and diagnostics, PSCs simplify compliance with functional safety regulations.

Enables Flexibility: They offer scalable, flexible solutions that can be easily adapted to complex and evolving safety requirements in modern machinery and processes.

Whether you are upgrading your current system or planning a new installation, adopting a Programmable Safety Controller in NZ is a forward-thinking investment in both safety and operational efficiency.

Real-World Application

From production lines to high-speed packaging units and robotic systems, safety PLCs play a pivotal role in minimising risks. In high-risk industries, even a minor fault can result in severe consequences—this is where the intelligent design of safety PLCs becomes invaluable.

Have you implemented a Programmable Safety Controller in your operations? What improvements—or challenges—have you experienced?

Get Expert Advice

Not sure where to start? Contact our team today to discuss your requirements. Whether you need technical guidance, system integration advice, or a pricing quote, our experts are here to help you find the right Programmable Safety Controller NZ solution for your business.