Machine Vision Inspection Systems

Vision Inspection Systems for Smarter Manufacturing

Automate Quality Control with Industrial Vision Systems

At ACSE Limited, we design and install high-performance machine vision systems that help New Zealand manufacturers automate inspection, reduce waste, and improve product consistency.

Whether you're checking for defects, verifying labels, or guiding robots, our vision systems deliver real-time accuracy, even in high-speed production environments.

What Our Vision Systems Can Do:

Detect product defects (scratches, dents, missing parts)

Read barcodes and QR codes

Verify label accuracy and orientation

Measure dimensions and alignment

Guide robotic arms for pick and place

Monitor fill levels and packaging integrity

Used Across Multiple Industries:

We work with clients across:

Food & Beverage

Pharmaceuticals

Dairy Processing

Packaging & Logistics

Manufacturing & Assembly

Each system is custom-engineered to match your line speed, lighting, product type, and factory layout.

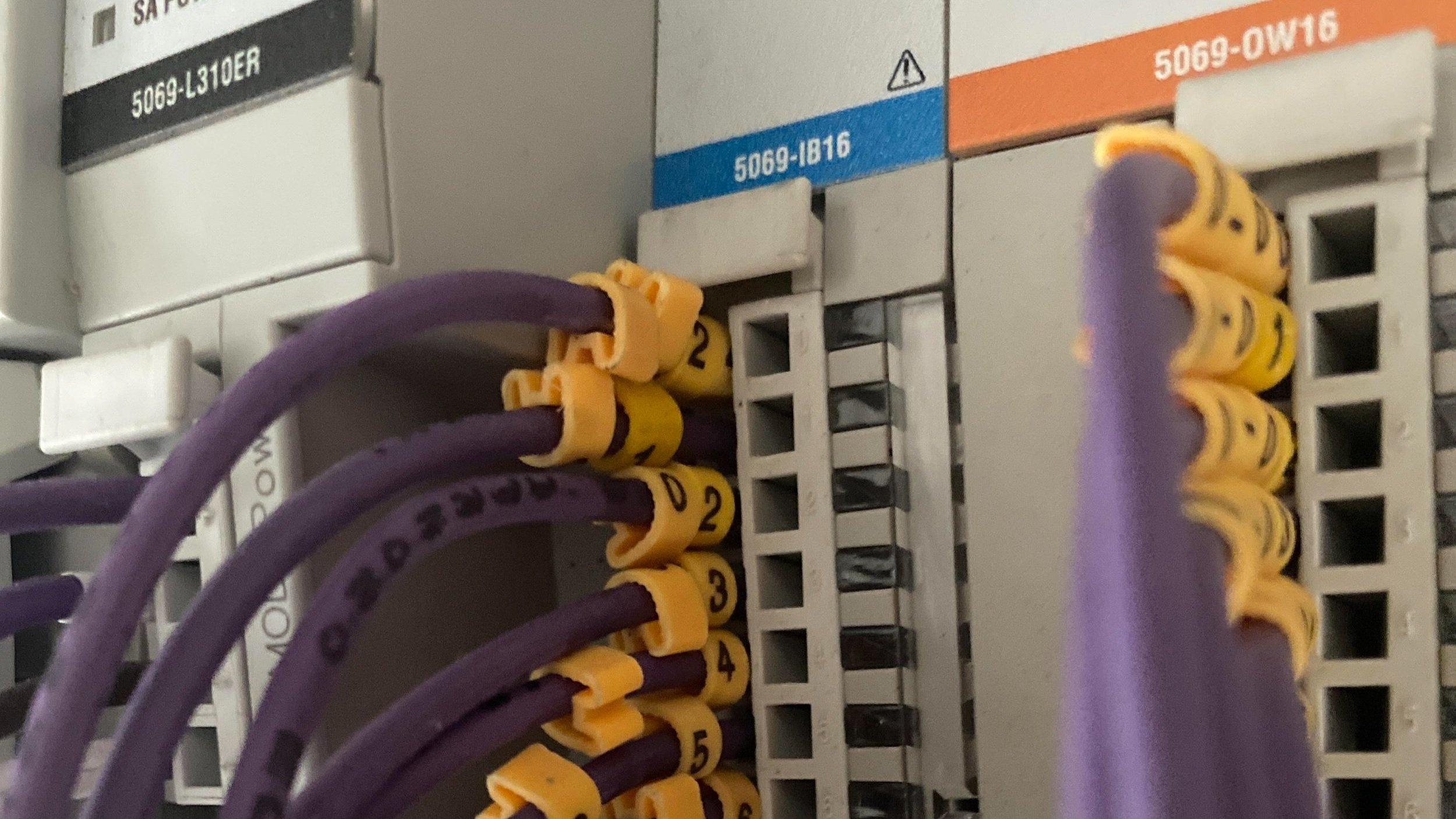

Integrated with PLCs and SCADA

Our vision systems are fully integrated with your existing PLC and SCADA platforms, enabling seamless data flow and instant feedback for automated rejection, batch tracking, and production reports.

Why Choose ACSE for Vision Inspection?

Local expertise with NZ-based support

Turnkey solutions from design to commissioning

Experience with leading brands

Robust systems built for 24/7 production

Improved accuracy, compliance, and ROI

Get a Free Consultation

Looking to automate your visual inspection process?

Contact us today to discuss a tailored solution for your production line.