Transforming Industries with Smart Manufacturing NZ

How to Reduce Labour Costs in Manufacturing Without Compromising Quality

Reducing labour costs in manufacturing is a top priority for plant managers, operations directors, and business owners — especially in high-wage economies like New Zealand. But cost-cutting doesn't have to mean job losses or reduced quality. Instead, it can be achieved through smart automation, process optimisation, and workforce upskilling.

With the rise of Smart Manufacturing NZ, companies are now embracing digital transformation strategies that allow them to reduce costs while staying competitive in both domestic and international markets.

Here’s how manufacturers are effectively reducing labour costs while increasing productivity:

1. Automate Repetitive Tasks

Automation is one of the most powerful tools to reduce reliance on manual labour. By integrating:

Robotic systems for palletising, packaging, and assembly

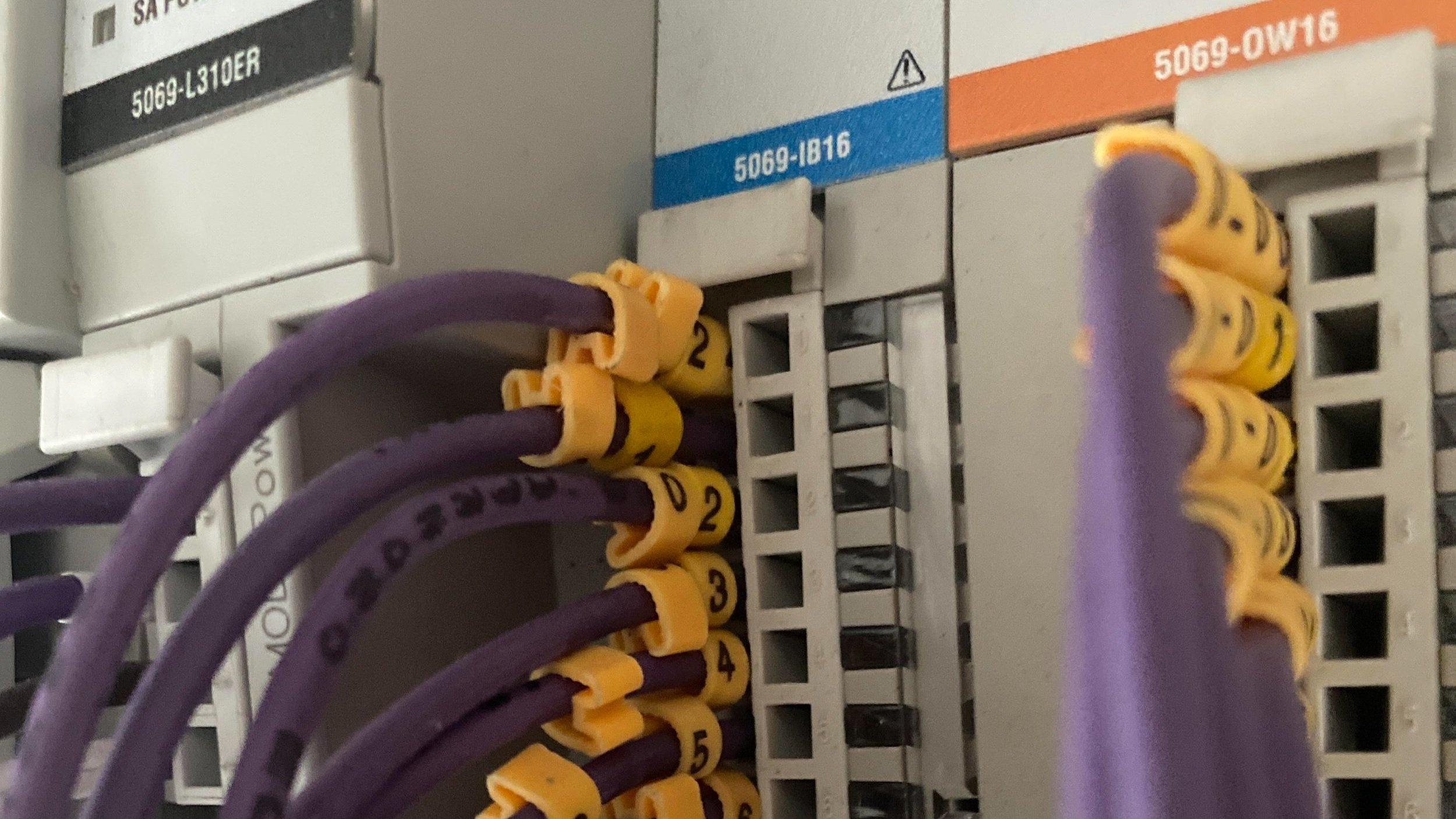

PLC-controlled machinery for consistent production

Vision inspection systems to ensure quality control

… you can free up human labour for higher-value tasks.

Bonus: Automation reduces rework and downtime, saving both time and money.

2. Invest in Industrial IoT (IIoT)

Smart factories powered by Industrial IoT (IIoT), also known as Internet of Things Industrial Automation NZ, can monitor machine performance in real-time, predict failures, and optimise energy and labour use. Data-driven insights help managers:

Identify bottlenecks

Reduce unplanned maintenance

Improve shift scheduling

All of which contribute to a leaner workforce and lower costs.

When combined with Smart Manufacturing NZ strategies, IIoT solutions ensure plants are not just automated but also data-driven, creating sustainable long-term savings.

3. Optimise Workflow & Layout

Poor factory layout leads to excessive movement, waiting times, and wasted effort. Lean manufacturing principles like 5S and Kaizen help streamline operations, reducing the number of workers needed per task or line.

4. Outsource Non-Core Functions

Outsourcing tasks like equipment maintenance, quality audits, or even automation engineering to specialised firms can significantly reduce in-house labour requirements — especially for SMEs. This approach allows businesses to focus on core production while keeping labour costs predictable and manageable.

5. Cross-Train Employees

Cross-training builds a more flexible and resilient workforce. When employees can operate multiple machines or handle multiple roles, you're less dependent on hiring for every task. It also improves employee engagement and reduces turnover costs.

6. Use Predictive Scheduling Software

Advanced scheduling software can align labour demand with actual production needs, avoiding overstaffing during slow periods or under-staffing during peaks. This creates a smoother workflow and reduces unnecessary payroll expenses.

7. Adopt Smart Manufacturing Practices

Smart Manufacturing NZ is about more than just automation — it’s about connecting people, machines, and processes in a way that maximises efficiency and reduces waste. This includes:

Integrating SCADA and machine vision systems for better decision-making

Using AI-driven analytics for predictive maintenance

Leveraging robotics for repetitive or hazardous tasks

Aligning digital twin technologies with real-time factory performance

By adopting these practices, manufacturers can significantly cut labour costs while improving quality, safety, and customer satisfaction.

ACSE Helps You Automate & Optimise

At ACSE Limited, we help New Zealand manufacturers reduce labour costs through tailored automation solutions — from robotic integration to machine vision systems and SCADA development.

Our expertise in Smart Manufacturing NZ ensures your plant stays future-ready, competitive, and efficient — without compromising on quality.